Contactez Changfu Chemical maintenant!

+86 27 8439 6550 | +86 181 6277 0058

Fabrication de pneus innovante : l'oligomère mercapto-silane de Changfu Chemical améliore les performances du caoutchouc

Dans la production de caoutchouc pour pneus, l'utilisation d'agents de couplage silane (comme le KH-590) entraîne la libération d'alcools. Un contrôle inapproprié du processus peut nuire à la densité du caoutchouc et à sa stabilité à long terme. L’équilibre entre la performance des matériaux et la fiabilité des processus reste une priorité de l’industrie.

La solution de Changfu Chemical : la valeur innovante des oligomères mercapto-silane

Forte de plusieurs années d'expérience en R&D dans les matériaux silanes, Changfu Chemical a lancé une nouvelle série d'oligomères mercapto-silane pour offrir de meilleures options pour les matériaux composites en caoutchouc :

Faible volatilité : en optimisant la structure moléculaire, il réduit considérablement la génération de substances volatiles lors de l'hydrolyse, améliorant ainsi l'uniformité interne du caoutchouc ;

Liaison interfaciale améliorée : la conception unique du groupe fonctionnel mercapto favorise la liaison chimique entre les charges et la matrice de caoutchouc. Des tests en laboratoire montrent qu'il peut améliorer les propriétés mécaniques des composites ;

Respectueux des processus : il permet d'obtenir des réactions de couplage efficaces à des températures douces, optimisant potentiellement la consommation d'énergie de production.

Données de laboratoire (basées sur des tests de formules typiques)

- Une nette tendance à la baisse du taux de défauts des bulles par rapport aux procédés traditionnels

-Amélioration significative des indicateurs dynamiques de génération de chaleur et de résistance au roulement

- Potentiel d'amélioration de l'efficacité de la vulcanisation et du contrôle des coûts

Les oligomères mercapto-silane de Changfu Chemical répondent aux normes environnementales strictes de l'industrie, avec des émissions de composés organiques volatils (COV) bien inférieures à celles des produits à base de silane traditionnels, aidant ainsi les entreprises à répondre aux besoins de mise à niveau des réglementations environnementales.

Orienté client, Changfu Chemical propose des solutions techniques personnalisées et un support complet du processus. Nous sommes impatients de travailler avec des partenaires mondiaux pour promouvoir le développement efficace et respectueux de l'environnement des matériaux en caoutchouc.

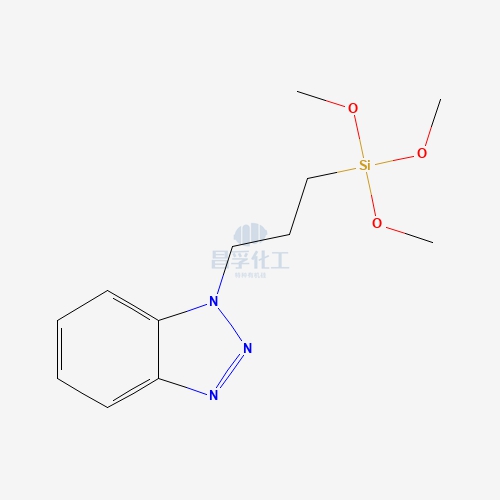

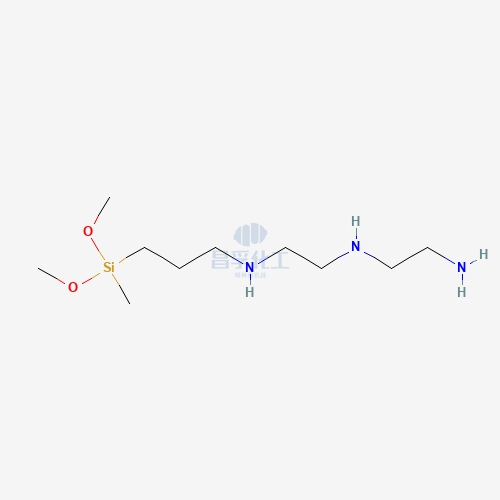

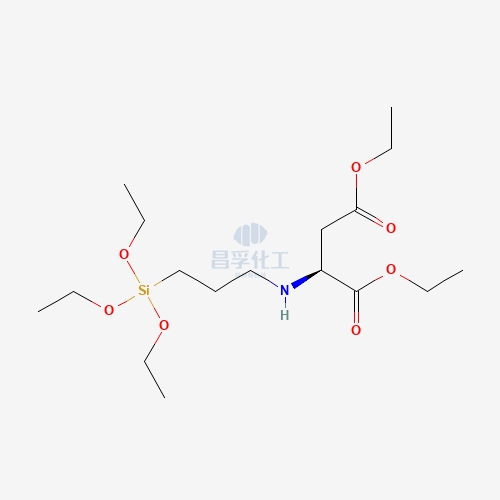

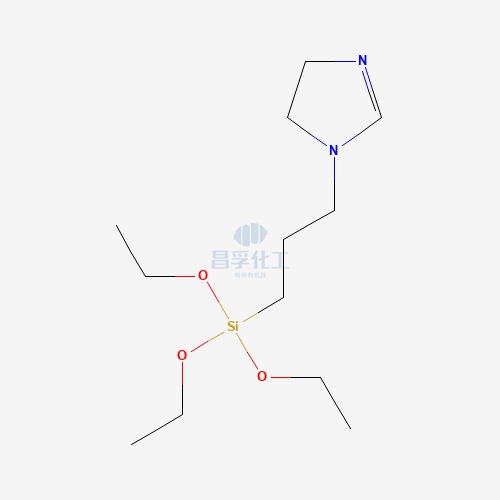

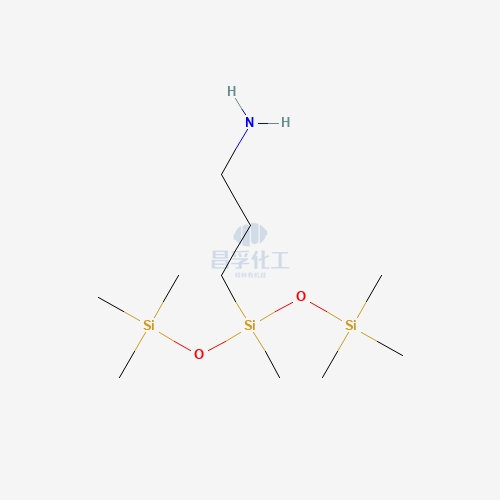

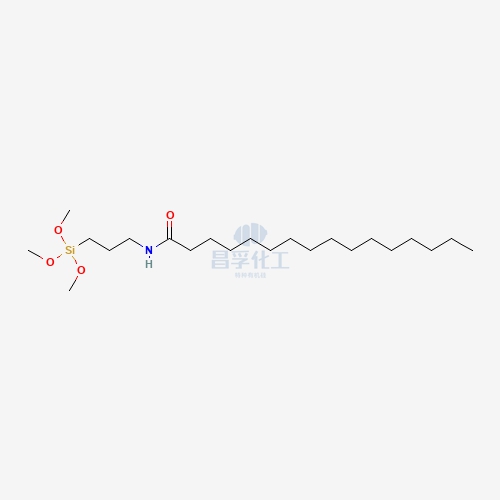

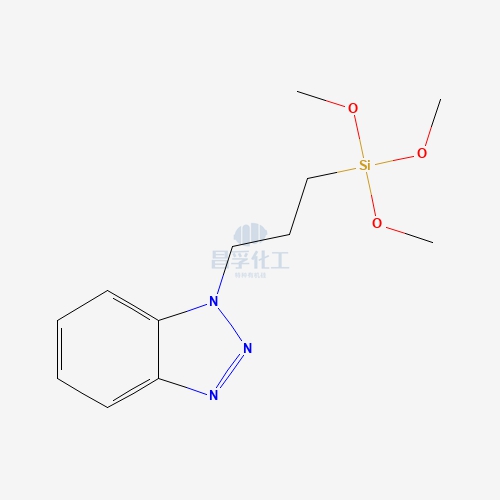

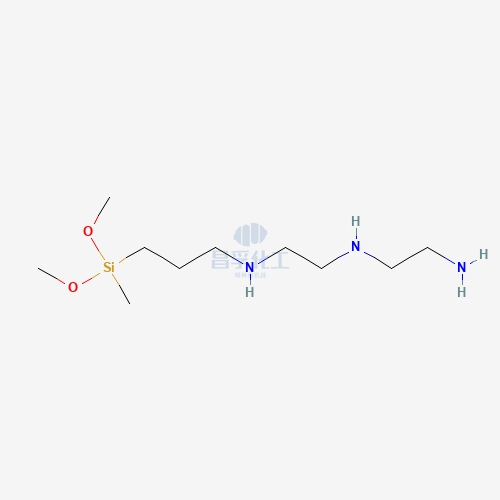

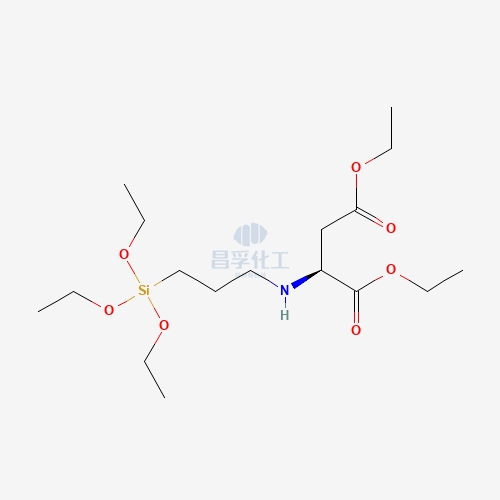

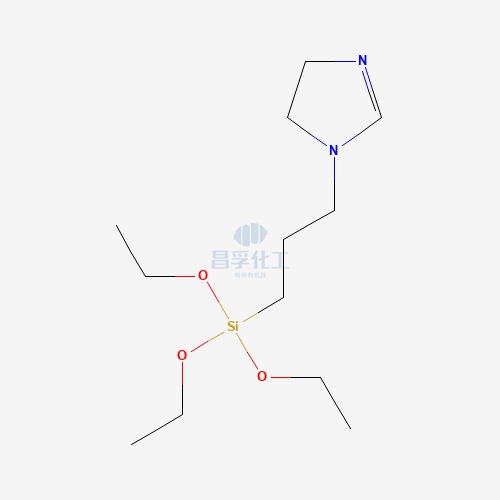

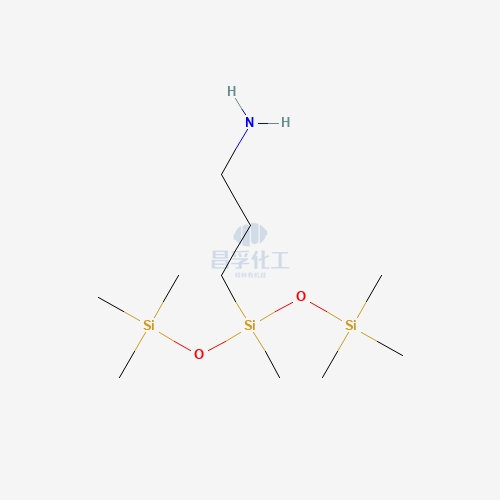

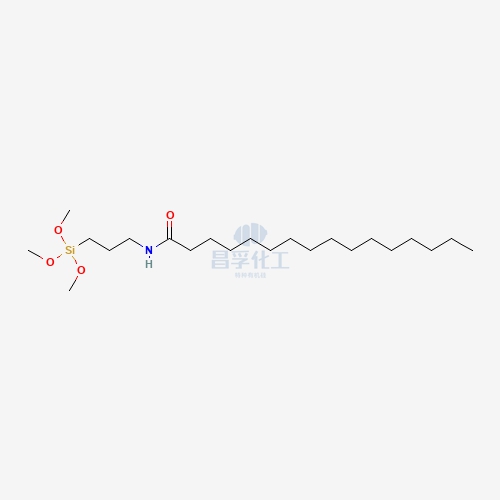

Composés de silicium populaires

Composés de silicium populaires

Nouvelles et blogs connexes

Nouvelles et blogs connexes

+86 27 8439 6550

+86 181 6277 0058

sales@cfsilanes.com

Optics Valley Bio-City

N ° 666, avenue Gaoxin

District de Hongshan, ville de Wuhan

+86 27 8439 6550 | +86 181 6277 0058

sales@cfsilanes.com

Optics Valley Bio-City

N ° 666, avenue Gaoxin

District de Hongshan, ville de Wuhan

Copyright © Hubei Changfu Chemical Co., Ltd. Tous droits